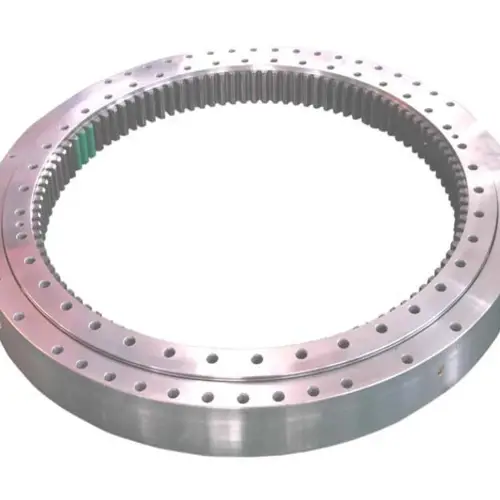

Customized Size High Quality Hobbing Internal Casting Heat Treated Inner Ring Gear

Our customized size high-quality hobbing internal casting heat treated inner ring gear is perfect for a variety of industrial applications. Made with stainless steel, iron, aluminum, bronze, carbon steel, brass, nylon and other high-quality materials, this gear is built to last. With ISO standard sizing and the ability to fulfill customer requirements, this gear is perfect for any project.

Product Parameters

Take a look at the specifications for our customized size high-quality hobbing internal casting heat treated inner ring gear:

| Product Name | Customized Size High Quality Hobbing Internal Casting Heat Treated Inner Ring Gear |

| Material | Stainless steel, iron, aluminum, bronze, carbon steel, brass, nylon, etc. |

| Size | ISO standard, customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| Surface Treatment | Carburizing and Quenching, Tempering, Tooth surface high quenching Hardening, Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding, etc. |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding, etc. |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping, gear accuracy testing |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment, sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102, Gear measurement center instrument CNC3906T and other High precision detection equipment |

Why choose our customized size high-quality hobbing internal casting heat treated inner ring gear?

We have been manufacturing gears for over 32 years and specialize in producing high-quality gears such as helical gear, bevel gear, spur gear, and grinding gear, gear shaft, timing pulley, rack, timing pulley and other transmission parts. Our products are made using high-quality materials and advanced processing equipment such as high-precision CNC gear grinding machines, high-speed CNC gear hobbing machines, CNC gear shaping machines, CNC lathes, CNC machining centers, and various grinding machines.

Our experienced technical workers ensure that we produce accurate and high-quality products that meet our customer’s needs. We regularly train our employees to ensure that we can produce high-precision and high-quality products that are more in line with our customers’ needs.

Other Industrial Products We Offer

Our company offers a variety of industrial products such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on offering high-quality products at preferential prices and providing considerate services. Customers are welcome to customize drawings and samples to meet their specific needs.

FAQs

1. What materials are used to make the customized size high-quality hobbing internal casting heat treated inner ring gear?

Our gear is made with high-quality materials such as stainless steel, iron, aluminum, bronze, carbon steel, brass, nylon and other materials to ensure durability and longevity.

2. Can you fulfill customer sizing requirements for the gear?

Yes, we can fulfill customer sizing requirements for the gear. We offer ISO standard sizing as well as the ability to customize sizing based on customer needs.

3. What types of processing methods are used to make the gear?

We use a variety of processing methods such as molding, shaving, hobbing, drilling, tapping, reaming, manual chamfering, grinding, and more to create the customized size high-quality hobbing internal casting heat treated inner ring gear.

4. What applications is this gear suitable for?

Our gear is suitable for a variety of applications such as toy, automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment, sanitation machinery, market/hotel equipment supplies, and more.

5. What testing equipment is used to ensure the quality of the gear?

We use a variety of testing equipment such as Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102, Gear measurement center instrument CNC3906T, and other high precision detection equipment to ensure the quality of our customized size high-quality hobbing internal casting heat treated inner ring gear.

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are only suitable for after-sales replacement and not as original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory.

Performance Characteristics of Internal Gear

Internal gear offers several performance characteristics that make it a valuable component in various applications. Firstly, its compact design allows for efficient power transmission in tight spaces. Secondly, the meshing of the gear teeth provides high torque capacity and smooth operation. Additionally, the internal gear’s ability to handle high loads and distribute stress evenly ensures its durability. Furthermore, its versatility allows for customization to suit specific application requirements. Lastly, the self-lubricating properties of internal gear reduce friction and extend its service life.

Types and Characteristics of Internal Gear

Internal gears can be classified into different types based on their tooth profile and application requirements. The most common types include spur, helical, herringbone, and double helical gears. Each type possesses unique characteristics that make it suitable for specific applications. For instance, spur gears are known for their simplicity and cost-effectiveness, while helical gears offer smoother and quieter operation. Herringbone gears provide improved load distribution and reduced axial thrust, making them ideal for high-load applications. Double helical gears, also known as herringbone gears, combine the advantages of helical and herringbone gears. They provide excellent load-carrying capacity and reduce gear noise.

Advantages of Internal Gear Materials

The choice of materials for internal gears greatly influences their performance and durability. Different materials offer varying advantages based on the requirements of the application. Steel internal gears are widely used due to their high strength and durability. They can withstand heavy loads and provide reliable performance. Cast iron internal gears offer excellent wear resistance and are suitable for applications where shock absorption is required. Additionally, nylon internal gears are lightweight, corrosion-resistant, and provide self-lubrication, making them ideal for applications with low noise requirements.

Application of Internal Gear

Internal gears find extensive applications in various fields, including Automotive Transmissions, Worm Gear Drives, Gear Pumps, Bicycles and Cycling Equipment, and Robotic Systems. In Automotive Transmissions, internal gears play a crucial role in transferring power from the engine to the wheels, ensuring smooth acceleration and efficient gear ratio changes. Worm Gear Drives utilize internal gears to achieve high torque transmission and self-locking capabilities. Gear Pumps employ internal gears to provide precise fluid displacement and efficient flow control. Bicycles and Cycling Equipment use internal gears for gear shifting and power transmission. Robotic Systems rely on internal gears for precise motion control and efficient power transfer.

Future Development Trends and Opportunities

The future of internal gear products looks promising, with several development trends and opportunities on the horizon. As technology advances, there is a growing demand for more compact and efficient gear systems, driving the need for innovative internal gear designs. The increasing focus on sustainability and energy efficiency also presents opportunities for the development of internal gears with reduced friction and improved performance. Furthermore, the expanding automation industry and advancements in robotics create a favorable environment for the application of internal gears in various robotic systems. Overall, the future holds immense potential for the continuous development and utilization of internal gear products.

Choosing a Suitable Internal Gear

Selecting the appropriate internal gear involves considering several key aspects. Firstly, the load requirements of the application must be carefully evaluated to ensure the chosen gear can handle the expected forces. Secondly, the gear ratio needs to be determined based on the desired speed and torque output. Material selection is crucial and should be based on factors such as strength, wear resistance, and corrosion resistance. Efficiency and backlash should also be taken into account to ensure smooth operation and minimal power loss. Additionally, mounting and space constraints should be considered when selecting an internal gear that fits within the available space.

In conclusion, internal gears offer exceptional performance characteristics, various types with unique advantages, and the ability to cater to different application requirements. Their extensive use across Automotive Transmissions, Worm Gear Drives, Gear Pumps, Bicycles and Cycling Equipment, Robotic Systems, and other fields highlights their value and importance. The future of internal gear products holds promising development trends and opportunities. When choosing a suitable internal gear, factors such as load requirements, gear ratio, material selection, efficiency and backlash, mounting, and space constraints should be carefully considered. By understanding these aspects, one can make informed decisions when selecting internal gears for their specific applications.

Author: Dream