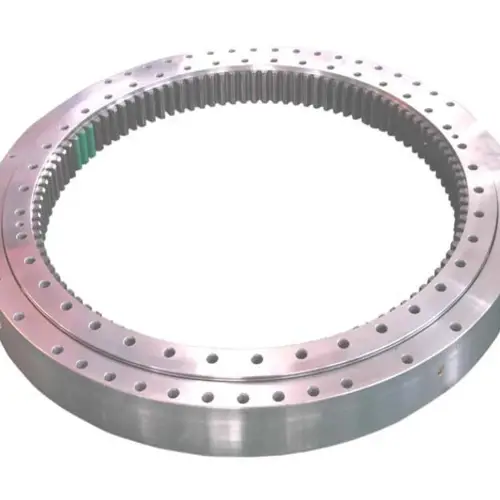

China Professional Customized Size High Quality Hobbing Internal Casting Heat Treated Inner Ring Gear air compressor for car

Product Description

High Hardened Forging Steel Inner Ring Gear Spur Helical Gear Spurs Wheel

Description:

The casting steel inner and outer ring gear is a high-quality and strong alloy steel gear commonly used in mechanical transmission. It is often made with a cast structure and undergoes surface carburizing or hardening treatment. This gear has high bearing capacity and durability, making it suitable for high-speed and heavy-load machinery. It provides stable transmission with low impact, vibration, and noise.

Characteristics:

1. Integration of factories and trade ensures strict control over every working procedure of the product.

2. Competitive quality and low price.

3. Advanced technology, professional packaging, fast delivery, and developed sea, land, and air logistics.

4. Timely after-sales service ensures a great user experience.

Application:

The casting steel inner and outer ring gear is widely used in various applications such as ladle turret, stacker crane, bucket wheel machine, solar heliostat tracking system, port crane, cabling machine, tower crane, offshore platform, ferris wheel, palletizing robot, rotary metallurgical furnace, can packing machine, wind blade transporter, shield tunneling machine, tube push bench, and excavator.

Packing & Delivery:

1. Filled with anti-rust oil.

2. Prevented from damage.

3. Delivered in perfect condition as per customers’ requirements.

4. Delivery on time as per the contract.

5. Shipping options available as per client request.

About us:

We are a leading industry transmission solutions manufacturer and service provider. Our product range includes customised gears, small gearmotors, industrial gearboxes, motors, and brand product sourcing. We cater to various industries such as chemicals, energy, material handling, environmental, extraction, pulp and paper, steel and metal, food and beverage, and construction. We pride ourselves on providing high-quality products at competitive prices, with timely response and sincere service. Customer satisfaction is our top priority.

Our Other Products:

- Agricultural Gearboxes

- Power Output Shafts

- Sprockets

- Fluid Couplings

- Worm Gear Reducers

- Gears and Racks

- Roller Chains

- Pulleys

- Planetary Gearboxes

- Timing Pulleys

- Bushings

Customers are welcome to customize drawings and samples. We take pride in offering high-quality products, competitive prices, and considerate services.

Frequently Asked Questions (FAQs):

1. What materials are the casting steel inner and outer ring gears made of?

The casting steel inner and outer ring gears are made of high-quality and strong alloy steel that undergoes surface carburizing or hardening treatment.

2. In which industries are the casting steel inner and outer ring gears commonly used?

The casting steel inner and outer ring gears are widely used in various industries such as mechanical transmission, high-speed machinery, and heavy-load machinery.

3. What are the key characteristics of the casting steel inner and outer ring gears?

The casting steel inner and outer ring gears have high bearing capacity, durability, stable transmission, low impact, and minimal vibration and noise.

4. What packaging and delivery options are available for the casting steel inner and outer ring gears?

The casting steel inner and outer ring gears are filled with anti-rust oil, packaged to prevent damage, and delivered in perfect condition as per customers’ requirements. We offer timely delivery as per the contract and can accommodate various shipping options as per client request.

5. What other products does your company offer?

In addition to the casting steel inner and outer ring gears, our company offers a wide range of industrial transmission products such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, and bushings.

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are only suitable for after-sales replacement and not as original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory.

Performance Characteristics of Internal Gear

Internal gear offers several performance characteristics that make it a valuable component in various applications. Firstly, its compact design allows for efficient power transmission in tight spaces. Secondly, the meshing of the gear teeth provides high torque capacity and smooth operation. Additionally, the internal gear’s ability to handle high loads and distribute stress evenly ensures its durability. Furthermore, its versatility allows for customization to suit specific application requirements. Lastly, the self-lubricating properties of internal gear reduce friction and extend its service life.

Types and Characteristics of Internal Gear

Internal gears can be classified into different types based on their tooth profile and application requirements. The most common types include spur, helical, herringbone, and double helical gears. Each type possesses unique characteristics that make it suitable for specific applications. For instance, spur gears are known for their simplicity and cost-effectiveness, while helical gears offer smoother and quieter operation. Herringbone gears provide improved load distribution and reduced axial thrust, making them ideal for high-load applications. Double helical gears, also known as herringbone gears, combine the advantages of helical and herringbone gears. They provide excellent load-carrying capacity and reduce gear noise.

Advantages of Internal Gear Materials

The choice of materials for internal gears greatly influences their performance and durability. Different materials offer varying advantages based on the requirements of the application. Steel internal gears are widely used due to their high strength and durability. They can withstand heavy loads and provide reliable performance. Cast iron internal gears offer excellent wear resistance and are suitable for applications where shock absorption is required. Additionally, nylon internal gears are lightweight, corrosion-resistant, and provide self-lubrication, making them ideal for applications with low noise requirements.

Application of Internal Gear

Internal gears find extensive applications in various fields, including Automotive Transmissions, Worm Gear Drives, Gear Pumps, Bicycles and Cycling Equipment, and Robotic Systems. In Automotive Transmissions, internal gears play a crucial role in transferring power from the engine to the wheels, ensuring smooth acceleration and efficient gear ratio changes. Worm Gear Drives utilize internal gears to achieve high torque transmission and self-locking capabilities. Gear Pumps employ internal gears to provide precise fluid displacement and efficient flow control. Bicycles and Cycling Equipment use internal gears for gear shifting and power transmission. Robotic Systems rely on internal gears for precise motion control and efficient power transfer.

Future Development Trends and Opportunities

The future of internal gear products looks promising, with several development trends and opportunities on the horizon. As technology advances, there is a growing demand for more compact and efficient gear systems, driving the need for innovative internal gear designs. The increasing focus on sustainability and energy efficiency also presents opportunities for the development of internal gears with reduced friction and improved performance. Furthermore, the expanding automation industry and advancements in robotics create a favorable environment for the application of internal gears in various robotic systems. Overall, the future holds immense potential for the continuous development and utilization of internal gear products.

Choosing a Suitable Internal Gear

Selecting the appropriate internal gear involves considering several key aspects. Firstly, the load requirements of the application must be carefully evaluated to ensure the chosen gear can handle the expected forces. Secondly, the gear ratio needs to be determined based on the desired speed and torque output. Material selection is crucial and should be based on factors such as strength, wear resistance, and corrosion resistance. Efficiency and backlash should also be taken into account to ensure smooth operation and minimal power loss. Additionally, mounting and space constraints should be considered when selecting an internal gear that fits within the available space.

In conclusion, internal gears offer exceptional performance characteristics, various types with unique advantages, and the ability to cater to different application requirements. Their extensive use across Automotive Transmissions, Worm Gear Drives, Gear Pumps, Bicycles and Cycling Equipment, Robotic Systems, and other fields highlights their value and importance. The future of internal gear products holds promising development trends and opportunities. When choosing a suitable internal gear, factors such as load requirements, gear ratio, material selection, efficiency and backlash, mounting, and space constraints should be carefully considered. By understanding these aspects, one can make informed decisions when selecting internal gears for their specific applications.

Author: Dream